About Company

Madras Radiators and Pressings Ltd – Plant4, a group company of apm, was established in the year 2007 to cater to sheet metal and punched components’ needs of various engineering sectors. The plant is located on the outskirts of Coimbatore the largest industrial city of Tamilnadu. It covers a total built area of over 40,000 sq. Feet

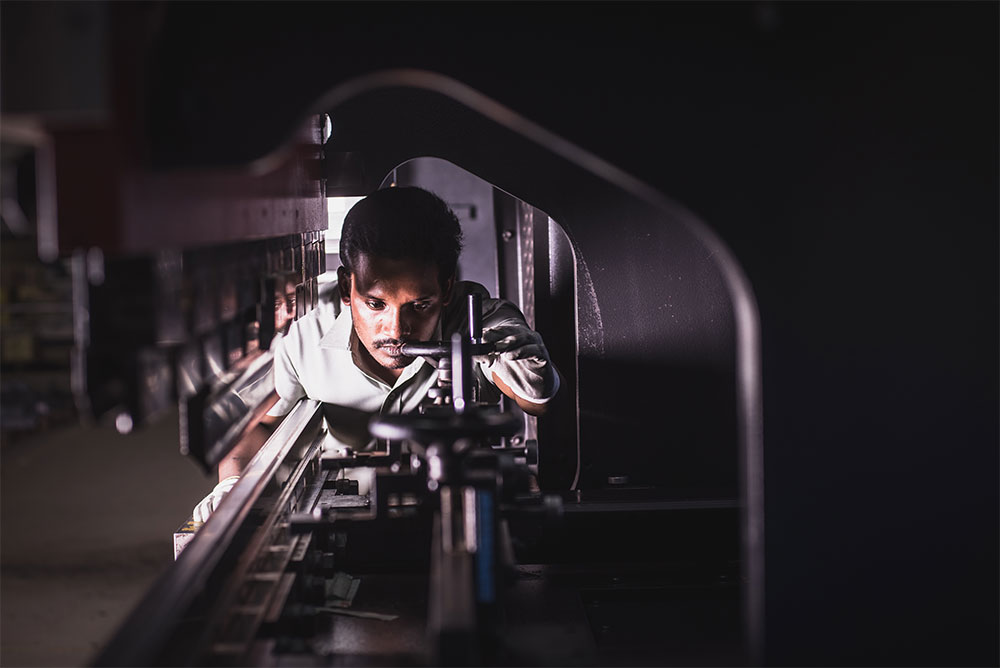

Today, a fully integrated and sophisticated manufacturing infrastructure coupled with technological superiority, finishing capability, and a well qualified manpower resource pool and an expanding product portfolio has put the company in a position to cater to diverse client base and provide end-to-end solution that meets customers expectations.

Years of experience and its commitment to quality have enabled the company to master the art of manufacturing sheet metal and punched components. The range of products manufactured at MRP Plant-4 benefits from the best of skills and facilities.

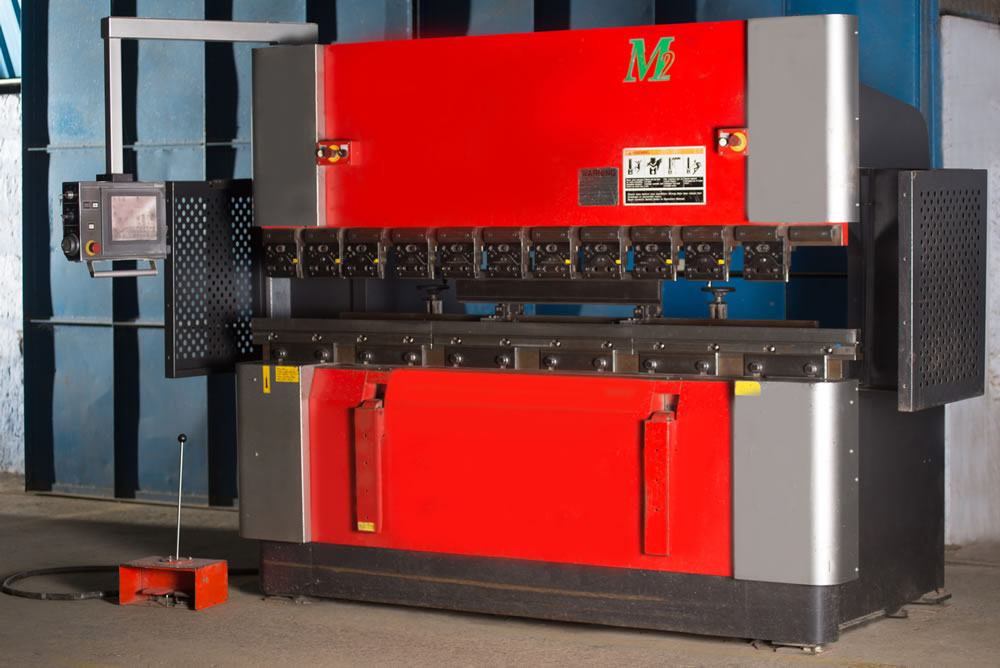

The plant is fully equipped with State-of-Art Laser cutting, TPP & Bending machines and a fully equipped assembly shop floor with latest hand tools, not to mention an In-house fabrication with powder coating facility.

Other machinery and equipment include a Laser Cutting Machine and a couple of 20 ton CNC turret punching machines manufactured in Germany and Japan. A 100 ton, 80 ton, 70 ton CNC press brake hydraulic machines and a hot Zinc phosphating pretreatment plant. The machine shop has a total capacity of over 120 tonnes per month.

A fully equipped welding department is housedin an area of over 5000 sq. feet with 6 numbers of MIG welding stations, 1 Spot welding and 10 work tables with buffing, deburring and grinding hand tools.

Following are the features that set us apart from our competitors

- State of the art infrastructure

- Variety of options for customization

- Reasonable pricing of our products

- Client-centric approach

- Ethical business practices followed by our organization

Quality

As we firmly believe quality plays a major role in manufacturing, our forte is to stick to our own quality inspection manual and ensure that every job is in accordance with all codes, standards and tolerances required by the customer using our calibrated instruments.

Added to all this infrastructure is a State-of-Art lab with instruments like Impact Tester, Conical mandrel tester, Salt spray chamber, Scratch Tester, Volumetric analysis facility etc and also has a liquid paint booth and a fully automated powder coating plant that translates plant 4 to a totally integrated plant.

Work Fields

Our manufacturing specializes in areas like cabinets, control panels, electronic enclosures, automobile components. We work with all types of sheets viz: mild Steel, stainless steel and aluminum.

Machines and technology are constantly updated to meet world’s standard.

And finally, We believe in teamwork and our team comprises of professionals who are highly specialized in their area of operations. The team is headed by dynamic management that strives to create a unique brand identity for MRP by leveraging its infrastructure capabilities and technical expertise. Other machinery and equipment include a Laser Cutting Machine and a couple of 20 ton CNC turret punching machines manufactured in Germany and Japan. A 100 ton, 80 ton, 70 ton CNC press brake hydraulic machines and a hot Zinc phosphating pretreatment plant. The machine shop has a total capacity of over 120 tonnes per month.